Polypropylene Mooring Tail

Description:

A polypropylene mooring tail is a type of synthetic rope or line used in maritime applications for mooring vessels. It is specifically made from polypropylene, a thermoplastic polymer known for its high strength, durability, and resistance to UV degradation and abrasion.

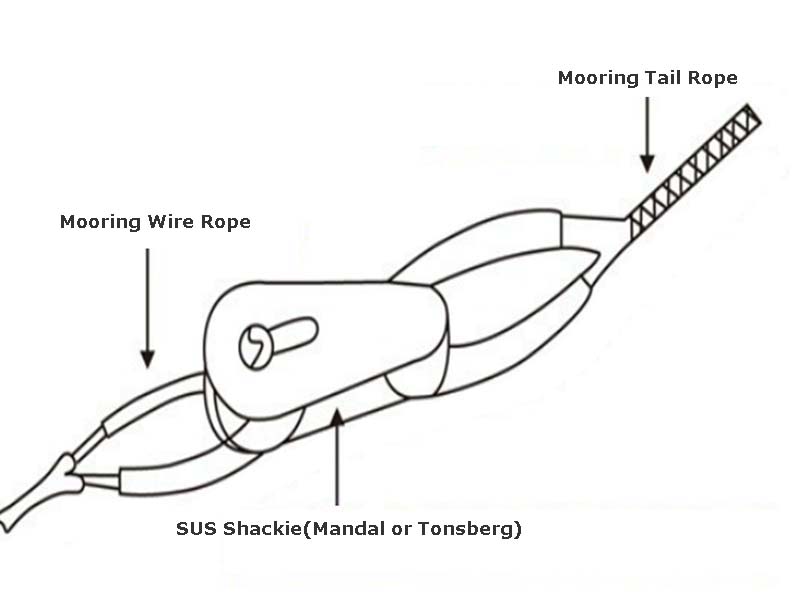

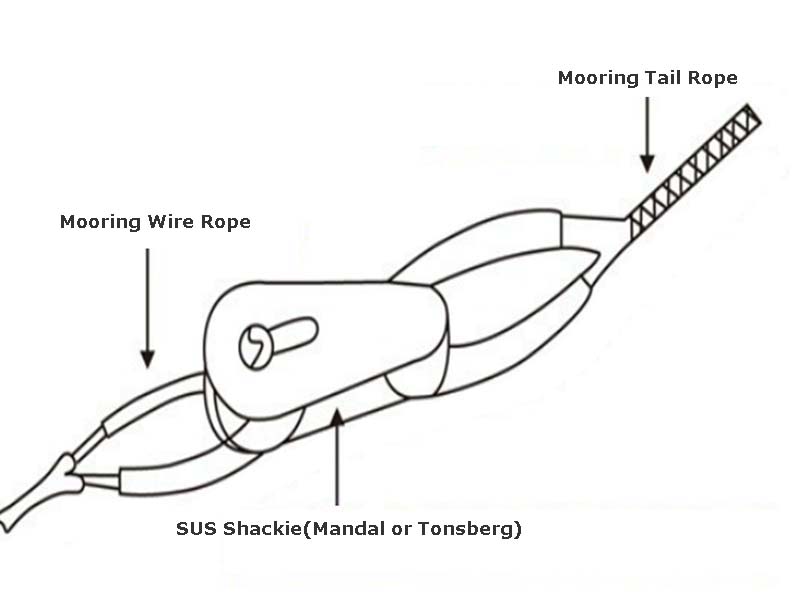

The mooring tail is an essential component of the mooring system, which is used to secure a vessel to a dock or an anchoring point. It acts as a flexible connection between the vessel and the mooring point, absorbing the dynamic forces and strains exerted on the vessel due to tidal movements, wind, and waves.

Polypropylene mooring tails are preferred in many marine applications due to their lightweight nature and excellent buoyancy. These properties make them easy to handle and deploy, reducing the risk of injury during mooring operations. The buoyancy of the mooring tail also helps to prevent it from sinking or getting entangled in propellers or other underwater structures.

In addition to their buoyancy, polypropylene mooring tails offer good elongation properties, allowing them to absorb shocks and jerks caused by sudden changes in vessel movements. This elasticity helps to minimize stress on both the vessel and the mooring system, providing a safer and more reliable mooring solution.

Polypropylene mooring tails are available in various lengths, diameters, and configurations to suit different vessel sizes and mooring requirements. They are often color-coded for easy identification and can be equipped with hardware such as thimbles or shackles for secure attachment to the vessel and mooring point.

It is important to note that while polypropylene mooring tails offer numerous advantages, they also have limitations. They have a relatively lower strength compared to other synthetic ropes or chains, making them more suitable for lighter vessels or in less demanding mooring conditions. Furthermore, they have a limited service life due to the effects of UV exposure, which can cause degradation and loss of strength over time.

Main Performance of Polypropylene Material:

- Material: Polypropylene fiber

- Strands: 3, 8, 12, or as required

- Specific Density: Approx. 0.91, Floating

- Melting point: Approx. 165℃

- Abrasion resistance: Medium

- UV resistance: Medium

- Chemical resistance: Good

- Temperature resistance: 70℃ Max

- Packing: Packaged with bags, standard export carton or as your request

- Certifications: ABS, CCS, ISO, NK, BV, LR, RS, etc.

SPM(Single Point Mooring Rope)

SPM(Single Point Mooring Rope) Mooring Tails

Mooring Tails Aramid Fiber Rope

Aramid Fiber Rope Nylon Single Filament 6-Ply Composite Rope

Nylon Single Filament 6-Ply Composite Rope Double-layer Multi-ply Braided Rope

Double-layer Multi-ply Braided Rope Hi-Sea Polyester Rope

Hi-Sea Polyester Rope