Large Ship UHMWPE Towing Rope and Mooring Rope

Description:

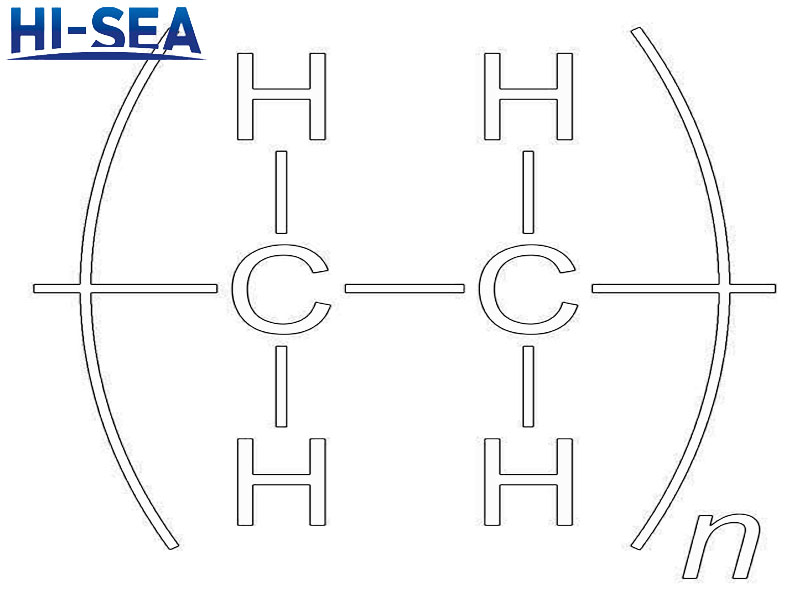

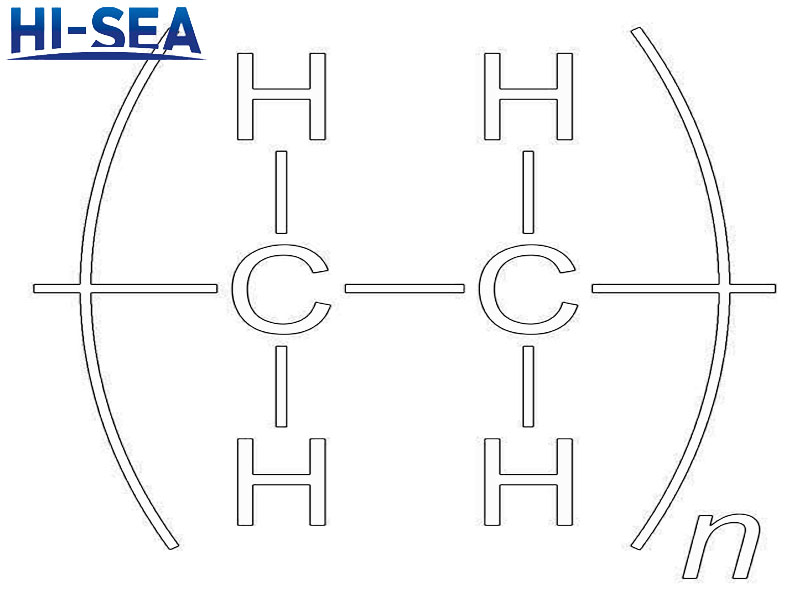

Large Ship UHMWPE Towing Rope and Mooring Rope is made of high-quality ultra-high molecular weight polyethylene fiber as the rope core. UHMWPE rope is the only fiber rope with density lower than 1, which can float on the water, but its strength is very high. Its superior comprehensive performance determines its irreplaceability in many scenes with strict requirements for ropes. Molecular formula: —(—CH2-CH2—)—n—, density: 0.920 ~ 0.964 g/cm3. The thermal deformation temperature (0.46 MPa) is 85℃ and the melting point is 130 ~ 136℃. The surface hardness, hardness, creep, bending strength, thermal deformation temperature and so on can be improved by filling and modifying UHMWPE.

(UHMWPE Molecular Structure)

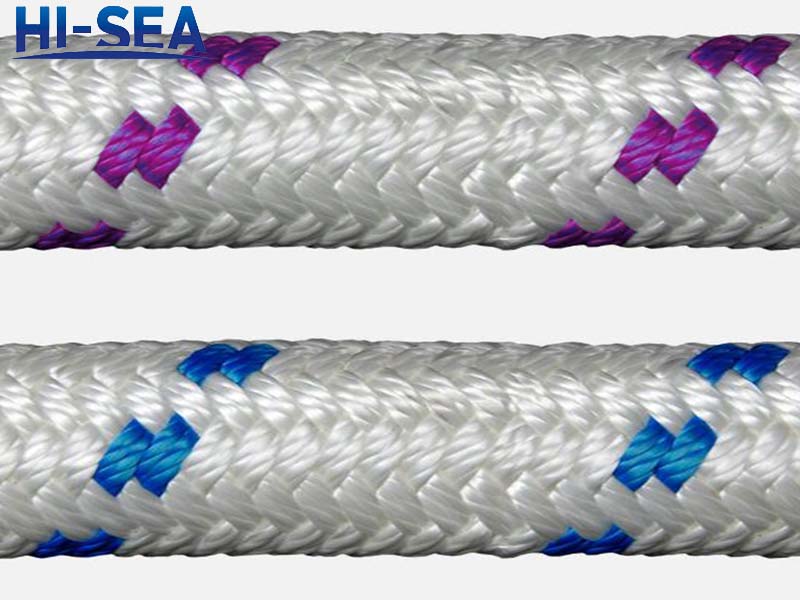

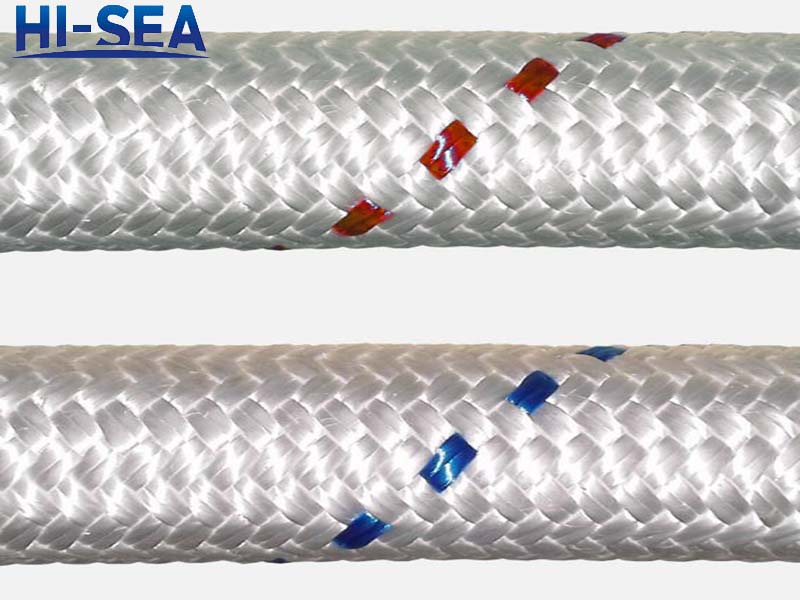

A Large Ship UHMWPE Towing Rope and Mooring Rope is a specialized type of rope designed for use in maritime industries to tow and moor large vessels. The rope is made from ultra-high molecular weight polyethylene (UHMWPE) fibers, which give it exceptional strength and durability. This type of rope is commonly used in the oil and gas industry, as well as for military and commercial applications. The UHMWPE fibers used in the rope have a high strength-to-weight ratio, making them ideal for use in applications where weight is a concern. Additionally, the rope is resistant to abrasion, chemicals, and UV light, which helps to prolong its lifespan. Large Ship UHMWPE Towing Rope and Mooring Rope comes in various sizes and strengths to accommodate different towing and mooring needs.

Measures to Prevent Ship Rope Breakage:

Adjust the stress of the ropes in time. With the progress of loading and unloading and the ebb and flow of tide, the on-duty personnel timely adjust the ropes to ensure the balanced stress of each rope.

Use qualified ropes. The aged and worn ropes should be replaced in time. Maintain the fairlead regularly. To prevent the rope from rubbing against the hull and causing cable breakage, the rubbed part can be wrapped with canvas or other wear-resistant materials.

Use the wharf spare rope. There should be enough thick ropes on the wharf, and during the flood season, the direction of the rising head of the ship should be forced to take them.

Anchoring and prepare the car. According to the actual water conditions, a water anchor can be thrown on the outboard side, and the force of the current on the cable can be reduced by using the grasping force of the anchor. Prepare the car before the rapids, and when the rapids come, the motor car can bear it, which can also reduce the stress on the mooring line. During the stormy weather, the tugboat can also be propped up.