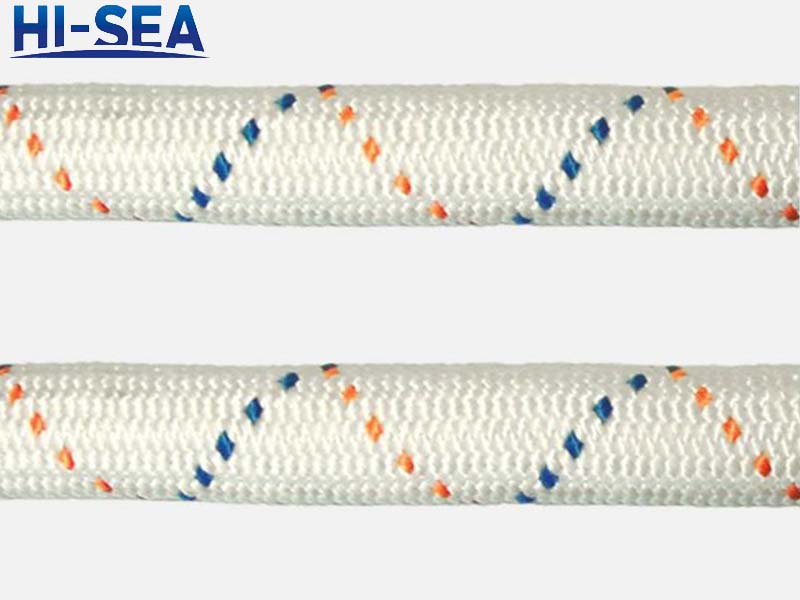

Multi-Color 12 Strands UHMWPE Rope

Description:

Ultra-high molecular weight polyethylene (UHMWPE) fiber is a kind of high-performance organic fiber successfully developed in the 20th century. The appearance of rope made of UHMWPE fiber has replaced the application of traditional steel wire rope. Compared with steel wire of the same diameter, the strength of UHMWPE fiber is about 1.5 times higher, the weight is about 85% lighter, it can float on the water surface, and it has the characteristics of wear resistance, softness, easy operation, high safety, corrosion resistance and aging resistance. As a heavy-duty rope in fishery and coastal industry, UHMWPE fiber rope is widely used for salvage, rescue, berthing, anchoring, towing, etc.

In recent years, with the rapid development of polymer chemistry, the types and technologies of coatings are constantly diversified. By adding different coatings, ropes with different properties can be obtained, such as increasing the water repellency of ropes, enhancing the mechanical properties of ropes, delaying the aging of ropes, prolonging the service life of ropes and improving the bending fatigue resistance of ropes. Nylon and other fibers are easy to absorb moisture. After moisture absorption, the weight of the rope increases, and the strength decreases correspondingly, and the wear resistance decreases. After moisture absorption and freezing, the rope loses its original softness and is not easy to operate. Therefore, on the basis of using UHMWPE fiber, this product ensures the excellent performance and operability of the rope by adding various types of coatings and colors, and can meet the requirements of customers for ropes in various usage scenarios.

Main Performance of UHMWPE Rope

- Material: Ultra-high molecular weight polyethylene;

- Strands: 8, 12 or as required;

- Color: According to your need;

- Specific Density: 0.97~0.98;

- Melting point: 165℃/260℃;

- Coil length: 220m;

- Spliced strength: ±10%;

- Weight and length tolerance: ±5%;

- Packing: Packaged with bags or as your requirements;

- Certifications: ABS, CCS, ISO, NK, BV, LR, RS, etc.