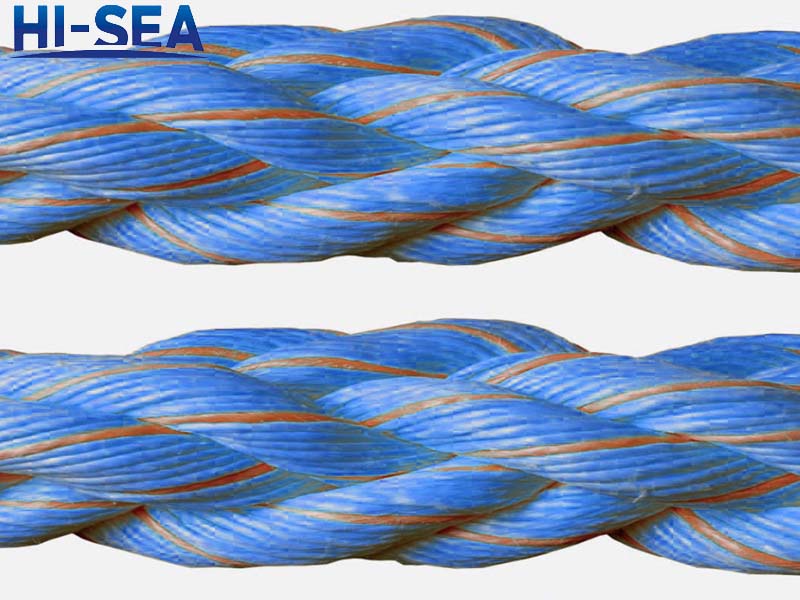

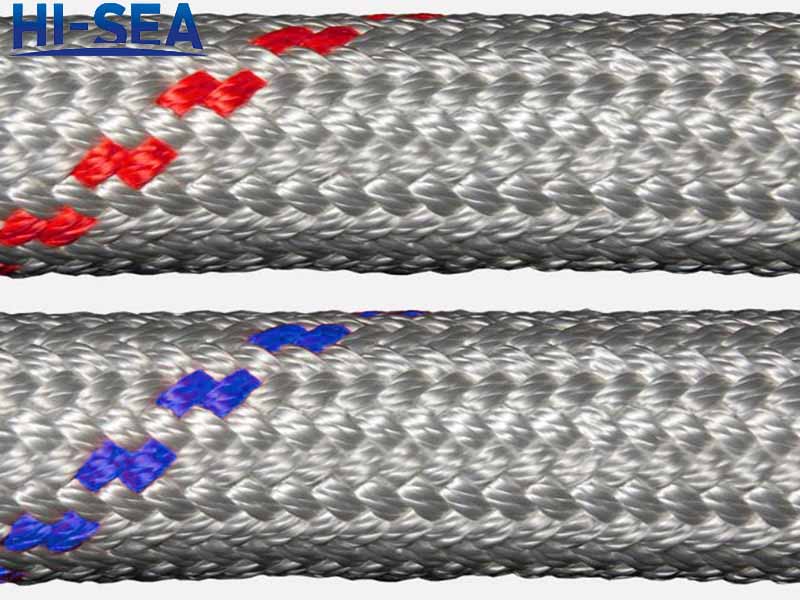

New Ultra-High Molecular Polyethylene Rope

Description:

The raw material of New Ultra-High Molecular Polyethylene Rope is a new type of ultra-high molecular weight polyethylene fiber. Ultra-high molecular weight polyethylene (UHMW-PE) is a new type of thermoplastic engineering plastic with incomparable performance advantages. At present, there is no single polymer material with so many excellent properties that it can become the “king of plastics”. UHMW-PE has the advantages of low friction coefficient, low wear, excellent chemical resistance, impact resistance, pressure resistance, frost resistance, heat preservation, self-lubrication, scaling resistance, stress cracking resistance and reproducibility. Among them, wear resistance, low temperature resistance, corrosion resistance, self-lubrication and impact resistance are the highest among all plastics.

Main Performance:

| Material |

Polyamide

multifilament |

Polyamide

yarn |

Polypropyle

multifilament |

Polypropylene |

Polyester |

| Spec.

Density |

1.14

not floating |

1.14

not floating |

0.91

floating |

0.91

floating |

1.27

not floating |

| Melting

Point |

215℃ |

215℃ |

165℃ |

165℃ |

260℃ |

| Abrasion

Resistance |

Very Good |

Very Good |

Medium |

Medium |

Good |

| U.V.

resistance |

Very Good |

Very Good |

Medium |

Medium |

Good |

| Temperature

resistance |

120℃ max |

120℃ max |

70℃ max |

70℃ max |

120℃ max |

| Chemical

resistance |

Very Good |

Very Good |

Good |

Good |

Good |

Ultra-high molecular weight polyethylene (UHMWPE) rope is a type of rope made from a synthetic material that is extremely strong, durable, and lightweight. It is commonly used in applications that require high tensile strength, such as mooring lines, towing ropes, and winch ropes.

The new generation of UHMWPE rope is made from an even higher molecular weight polymer, which gives it even greater strength and durability than previous versions. This new rope is made through a process known as gel spinning, which aligns the polymer molecules in a specific direction to optimize strength.

The new UHMWPE rope has a number of benefits over traditional ropes, including increased strength, reduced weight, and improved resistance to abrasion and UV radiation. It is also highly resistant to chemicals and does not absorb water, which can cause degradation and weakening of the rope over time.

Due to its many advantages, the new UHMWPE rope is finding increasing use in a variety of applications, from marine and offshore industries to aerospace and defense. It is expected to continue to replace traditional ropes in many applications due to its superior performance and longevity.

Material Advantage:

1. Low density and good flexibility: the density of UHMWPE is lower than that of other engineering plastics.

2. Good wear resistance: The wear resistance of UHMWPE is directly proportional to the molecular weight, and the higher the molecular weight, the better its wear resistance.

3. Good self-lubrication: UHMWPE has a very low friction coefficient (0.05 ~ 0.11), and UHMWPE is known as a friction material with ideal cost/performance in tribology.

4. Good impact resistance: UHMWPE has excellent impact energy absorption, and the impact energy absorption value is the highest among all plastics, so the noise damping performance is also very good.

5. Good chemical corrosion resistance: Based on the fact that ultra-high molecular weight polyethylene is a saturated molecular cluster structure, it has extremely high chemical stability, and can withstand various corrosive media (acid, alkali, salt) and organic media in a certain temperature and concentration range except for strong oxidizing acid.

6. High tensile strength: UHMWPE has incomparable ultra-high tensile strength because of its necessary structural characteristics towards tensile orientation.

7. Good weather resistance and aging resistance: on the one hand, UHMWPE fiber rope has a high molecular weight; on the other hand, the service life of UHMWPE rope is much longer than that of other common ropes by adding an anti-aging agent.

8. Low water absorption: the water absorption of UHMWPE is very low; Generally less than 0.01%, only 1% of PA66.

9. Hygiene and non-toxicity: UHMWPE is hygienic and non-toxic, fully conforms to the standards of Japan Health Association, and is recognized by the US Food and Drug Administration and the US Department of Agriculture, and can be used to contact food and drugs.