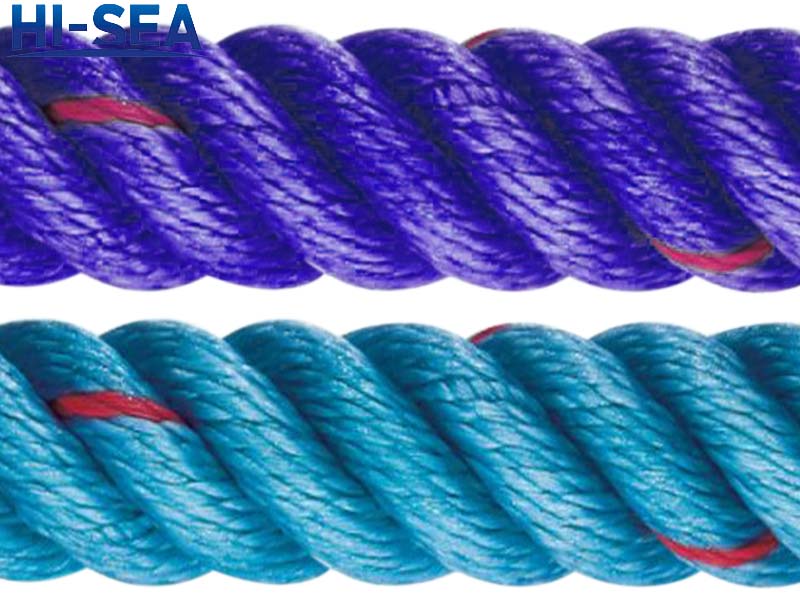

Polypropylene (PP) and Polyether Sulfone (Pes) Mixed Tanker Mooring Rope

Description:

The Polypropylene (PP) and Polyether Sulfone (PES) mixed tanker mooring rope is a specialized type of rope designed for use in securing tankers during mooring operations. It is a unique blend of two distinct materials, combining the favorable characteristics of both polypropylene and polyether sulfone to create a high-performance rope with exceptional strength, durability, and resistance to various environmental conditions.

Polypropylene, a thermoplastic polymer, is known for its excellent strength-to-weight ratio, low moisture absorption, and high resistance to abrasion and UV radiation. It is lightweight, buoyant, and exhibits good chemical resistance, making it suitable for marine applications. Polypropylene fibers are often used in ropes due to their high tensile strength and flexibility.

Polyether sulfone, on the other hand, is a high-performance thermoplastic known for its excellent thermal stability, mechanical strength, and resistance to chemicals and hydrolysis. It can withstand high temperatures and harsh environments, making it ideal for demanding applications. Polyether sulfone fibers enhance the overall strength and thermal resistance of the mooring rope.

By combining these two materials, the mixed tanker mooring rope capitalizes on the strengths of both polypropylene and polyether sulfone. The resulting rope offers superior tensile strength, excellent resistance to chemicals, UV radiation, and abrasion, and can withstand extreme temperatures and prolonged exposure to harsh marine conditions.

The mixed tanker mooring rope is designed to withstand the dynamic loads and stresses experienced during tanker mooring operations, ensuring the safety and stability of the vessel. Its buoyancy and flexibility allow for easy handling and deployment, while its robust construction provides reliable performance and longevity.

Performance of Polyethersulfone Material:

| Density |

1.37 ~ 1.51g/cm3 |

| Bending strength |

> 130MPa |

| Impact strength |

> 78.0J/m |

| Water absorption(23℃, 4h) |

<0.40%% |

| Tensile strength |

> 85.0MPa |

| Volume resistivity |

1016 ~ 1017 Ω.cm |