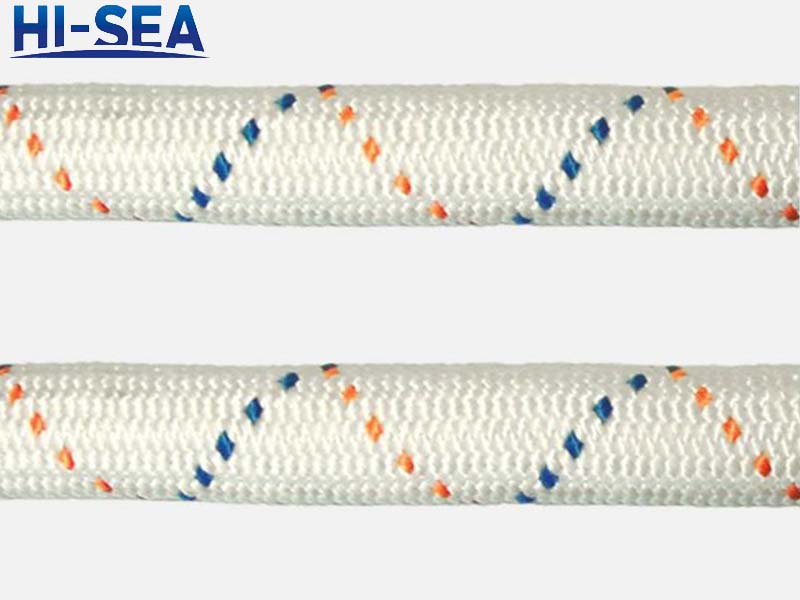

12 Strands 100% UHMWPE Fiber Rope and Hmpe Rope Are Used for Ships

Description:

Ultra-High Molecular Weight Polyethylene (UHMWPE) fibers are widely used in ropes and lines for the marine industry due to their high strength and low weight. These ropes are commonly known as HMPE (High Modulus Polyethylene) ropes.

12 strands 100% UHMWPE fiber ropes are an excellent choice for mooring, towing, and anchoring operations on ships. They are incredibly strong and lightweight, with a higher strength-to-weight ratio than steel wire ropes. These ropes are also more durable and have a longer lifespan than other synthetic ropes, such as nylon or polyester.

HMPE ropes are resistant to abrasion, UV rays, and chemicals, making them suitable for use in harsh marine environments. They also have low elongation, which means they don’t stretch much under load, making them ideal for operations where precise control is required, such as mooring.

Overall, the use of 12 strands 100% UHMWPE fiber ropes and HMPE ropes can improve the safety and efficiency of marine operations while reducing the weight and maintenance costs of equipment on ships.

Product Specifications:

| Material: |

UHMWPE |

| Strands: |

8, 12, 16 or as required |

| Specific Density: |

0.97, Floating |

| Melting point: |

145℃ |

| Abrasion resistance: |

Good |

| UV resistance: |

Excellent |

| Chemical resistance: |

Excellent |

| The elongation: |

3~4% |

Main Features:

1. Simpler and safer operation.

2. Easy to splice and more efficient.

3. Flexible, free from kinking and rotation.

4. Low elongation and ultra-low water absorption.

5. Compared with steel wire, the service life is longer.