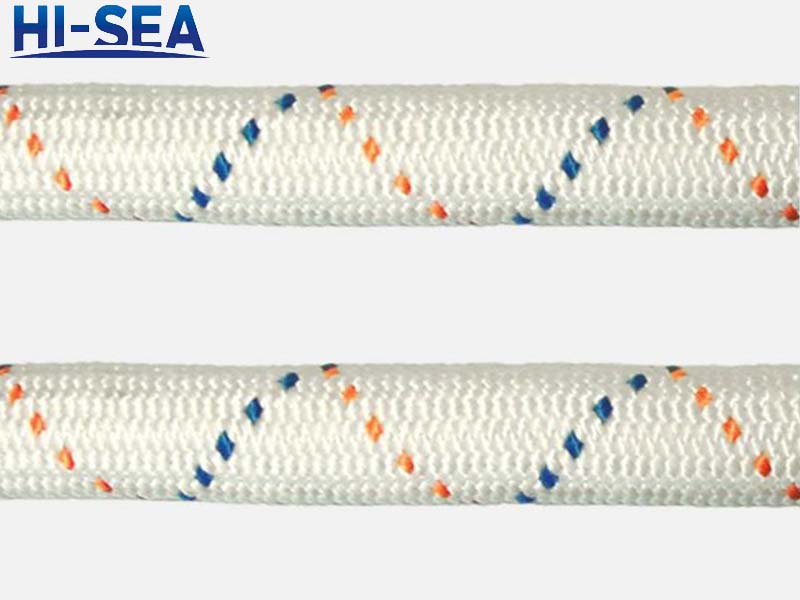

12 Strands of Double-Layer Braided Wharf Rope

Description:

The 12 strands of double-layer braided wharf rope are a robust and durable type of rope used primarily in marine applications, especially in wharfs and docks. This specific design combines two layers of braiding to create a strong and reliable structure.

Each strand is meticulously crafted using high-quality synthetic fibers or natural materials, depending on the specific requirements and intended use. The double-layer braiding technique involves intertwining two sets of six strands, resulting in a total of 12 strands that work together to provide exceptional strength and load-bearing capacity.

The construction of the rope involves a complex weaving pattern, where the strands intertwine diagonally to form a tightly woven, interlocking network. This intricate arrangement ensures that the load is distributed evenly across the entire rope, preventing weak points and reducing the risk of failure under heavy loads or harsh environmental conditions.

The double-layer braided wharf rope offers several advantages. Its design enhances its ability to absorb and distribute shock, making it ideal for applications that involve heavy lifting, towing, or securing vessels at wharfs and docks. The strong and resilient nature of the rope enables it to withstand the forces exerted by tides, waves, and wind, ensuring reliable mooring and safe operations.

Furthermore, the double-layer braiding adds an extra layer of protection to the rope, enhancing its resistance to abrasion, UV radiation, and other forms of wear and tear. This feature significantly extends the rope’s lifespan, reducing the need for frequent replacements and providing long-term cost savings.

Main Performance of Polyethylene Material:

| Material |

Polyethylene fiber |

| Spec. density |

Approx. 0.91, Floating |

| Melting Point |

Approx. 165℃ |

| U.V. Resistance |

Medium |

| Abrasion resistance |

Medium |

| Chemical resistance |

Good |

| Temperature Resistance |

Approx. 70℃ Max |

Specification of Polyethylene Fiber Rope:

1. Material: Polyethylene fiber(PP)

2. Strands: 8, 12, 16 strands or as required

3. Color: Different colors on reqirement

4. Melting point: Approx. 165℃

5. Packing: Packaged with bags, standard export carton or as your request

6. Application: Mooring, Anchoring, Towing, Leisure, Agriculture, Fishing etc

7. Certifications: ABS, CCS, ISO, NK, BV, LR, RS, etc