With Splice Eyes Both End of 12 Strands UHMWPE Rope

Description:

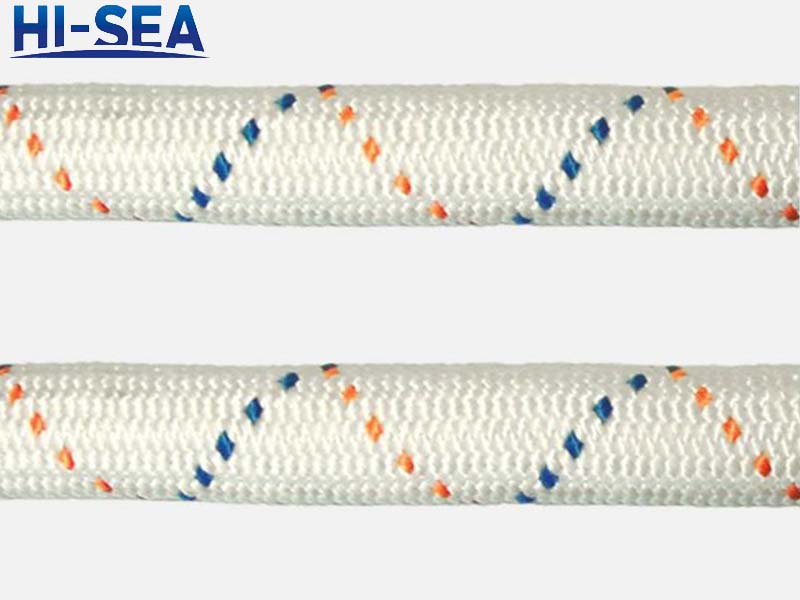

Splicing is a technique used to join two ropes or to create a loop at the end of a rope. In this case, the rope being spliced is a 12-strand UHMWPE rope, which is a high-strength, low-stretch synthetic fiber rope. The splicing process involves weaving the individual strands of the rope together, typically using a fid, which is a tool used to manipulate the rope’s fibers.

The unique feature of this spliced rope is that it has “splice eyes” at both ends, which are loops created by the splicing process. These splice eyes provide a secure and strong attachment point for the rope, allowing it to be easily fastened to other objects or used as part of a rigging system.

Splicing the ends of a 12-strand UHMWPE rope with splice eyes is a common and effective way to create a strong, versatile, and reliable rope for a variety of applications, such as in marine, industrial, or outdoor settings.

Product Specifications:

| Material: |

UHMWPE and Polyester |

| Strands: |

8, 12, 16 or as required |

| Specific Density: |

0.97, Floating |

| Melting point: |

145℃ |

| Abrasion resistance: |

Good |

| UV resistance: |

Excellent |

| Chemical resistance: |

Excellent |

| The elongation: |

3~4% |

| Coil length: |

220m |

| Spliced strength: |

±10% |

| Weight and length tolerance: |

±5% |

Main Performance:

1. Faster: Using rope mooring made of ultra-high molecular weight polyethylene can save more time for ships to berth.

2. Safer: The cable made of ultra-high molecular weight polyethylene is light in weight and soft, and the elongation of the fiber formed by floating water is low, so it is safer to use.

3. More environmentally friendly: only minimal maintenance is required after leaving Hong Kong, and there is no oil pollution, which is very environmentally friendly.

4. Economical: Reasonable use, the cable has a service life of more than ten years.