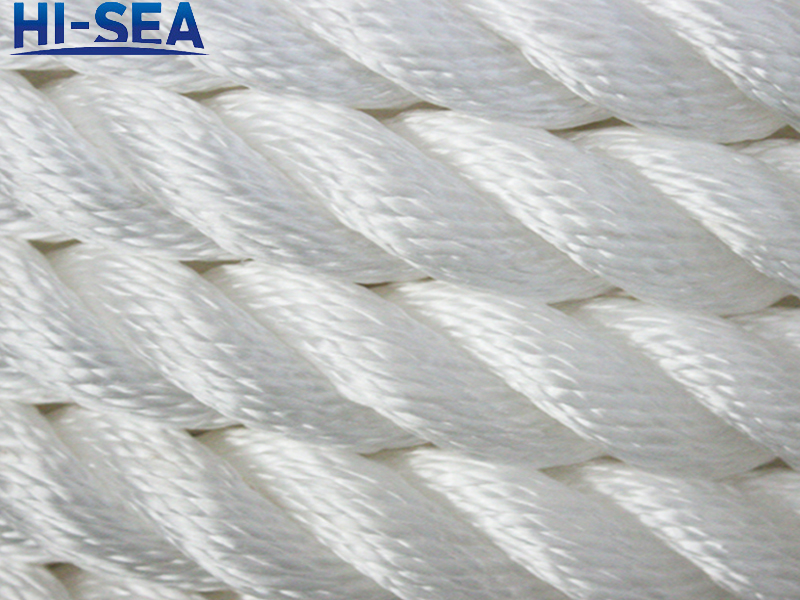

3-Strand Low Elongation Durable UV-Resistant Polypropylene Rope

Description:

History: In 1954, G. Natta first polymerized propylene into polypropylene (using aluminum-titanium chloride as catalyst), and founded the theory of directional polymerization, which attracted people’s attention. From the late 1960s to the mid 1970s, polypropylene entered a period of great development. Since 1980s, the output of polypropylene has been in the forefront of synthetic resins, and now it is only lower than polyethylene, ranking second.

A 3-strand low elongation durable UV-resistant polypropylene rope is a type of rope that consists of three twisted strands of polypropylene fibers. It has low elongation or stretch, making it suitable for applications that require minimal stretch or sag.

This rope is highly durable and resistant to UV radiation, which means it can withstand exposure to sunlight and other environmental elements without degrading or losing its strength over time. This makes it ideal for use in outdoor environments, such as in boating, camping, or other outdoor activities where the rope will be exposed to the elements.

Polypropylene is a lightweight and strong synthetic fiber that is commonly used in ropes because it is resistant to moisture, chemicals, and abrasion. This rope is also easy to handle and knot, making it an excellent choice for a variety of applications.

Overall, a 3-strand low elongation durable UV-resistant polypropylene rope is a versatile and reliable option for a range of tasks, whether it be for recreational or industrial purposes.

Main Performance:

| Material |

Polypropylene fiber |

| Strands |

3, 8, 12 or as required |

| Color |

Different colors or as your request |

| Specific Density |

Approx. 0.91, Floating |

| Melting point |

Approx. 165℃ |

| Abrasion resistance |

Medium |

| UV resistance |

Medium |

| Chemical resistance |

Good |

| Packing |

Bags, standard export carton or as your request |

| Certifications |

ABS, CCS, ISO, NK, BV, LR, RS, etc. |