3 Strands High-Strength and High-Modulus Polyethylene Rope

Description:

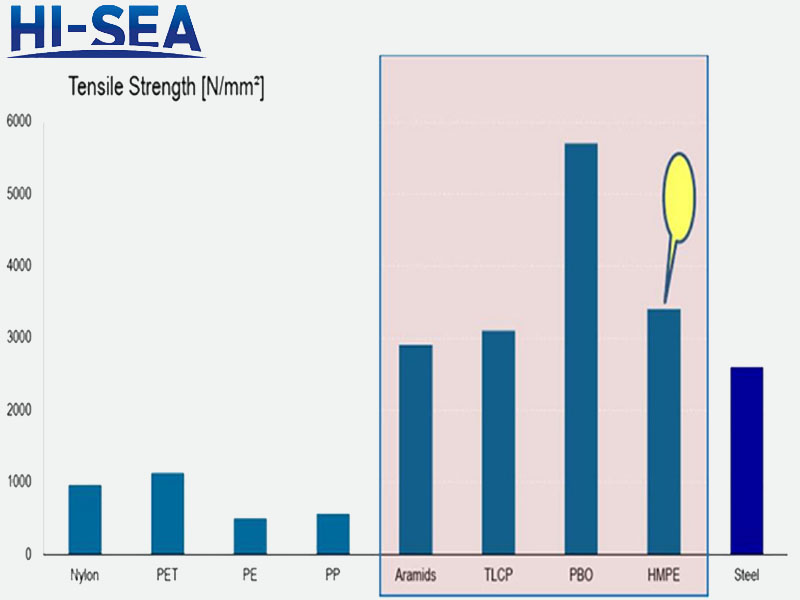

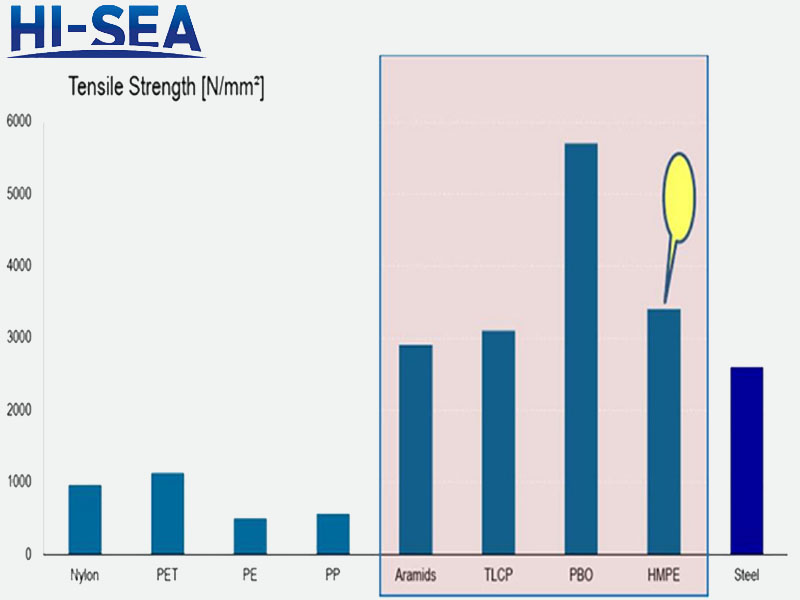

The rope is made of high-molecular polyethylene fiber, which has the highest strength among synthetic fibers. Its strength can reach 1.5 times that of steel wire of the same specification, and its elongation is very low, which is comparable to the breaking elongation of metal steel wire. The rope made of it has the characteristics of ultraviolet radiation resistance, seawater resistance, acid and alkali resistance, fatigue resistance, weather temperature difference resistance, prolonged service life and so on. The super-strength and special high-quality performance of polyethylene rope has become the first choice for special industries, and is widely used in the fields of national defense, special ships, offshore oil and ocean transportation.

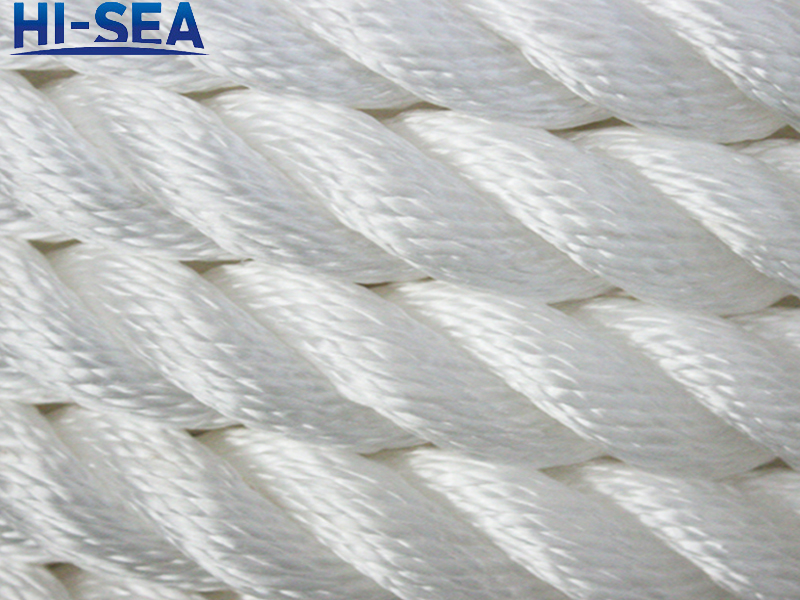

One common variation of this rope is the 3 strands high-strength and high-modulus polyethylene rope. As the name suggests, this rope is made up of three individual strands of UHMWPE fibers, each twisted together to form a single rope.

These ropes have a very high strength-to-weight ratio, meaning they can support heavy loads while still being relatively lightweight. They also have low elongation, which means they don’t stretch as much under load as other types of rope.

This type of rope is commonly used in a variety of applications, including mooring lines, tow ropes, winch lines, and even in some climbing and rescue scenarios. However, it is important to note that while these ropes are incredibly strong, they can still be subject to abrasion, UV damage, and other types of wear and tear, so regular inspection and maintenance is crucial to ensure their safe and effective use.

Main Performance of HMPE Marine Mooring Rope:

| Material |

High-Molecular Polyethylene Fiber |

| Specific gravity |

Approx. 0.98, Floating |

| Melting point |

Approx. 145℃ |

| UV resistance |

Good |

| Chemical resistance |

Very good |

| Abrasion resistance |

Very good |

Specification of HMPE Marine Mooring Rope:

1. Material: High-Molecular Polyethylene Fiber

2. Strands: 3, 8, 12, or as required;

3. Color: As your needs;

4. Specification: 6mm-40mm or on request;

5. Packing: Packaged by coil or reel or as your request;

6. Certifications: ABS, CCS, ISO, NK, BV, LR, RS, etc;

7. Applications: Mooring line, Tug line, Super sized commercial vessel, Wire rope replacement, etc;