3-Strand HMPE Sling, Winch Rope

Description:

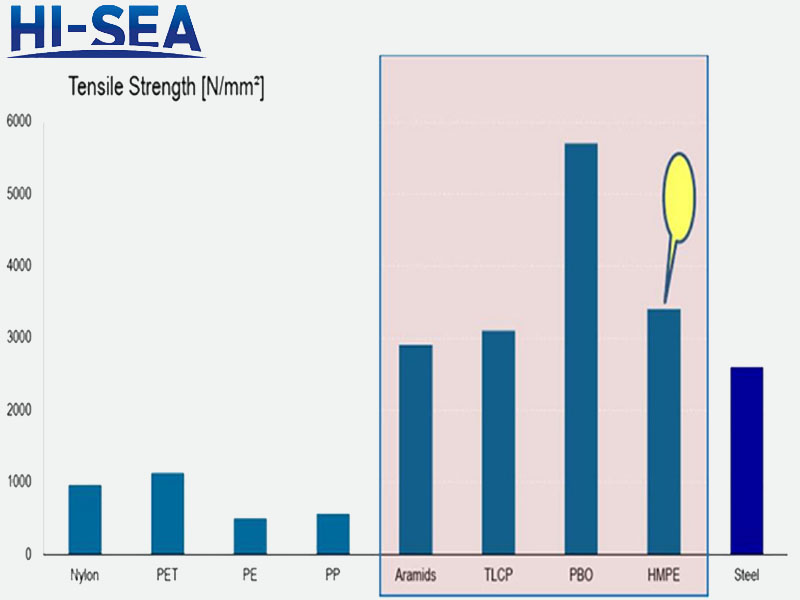

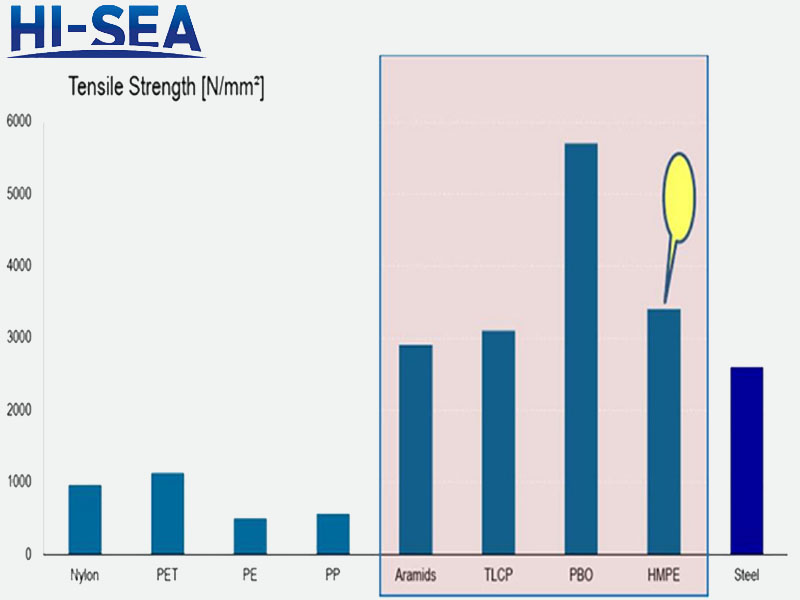

3-Strand HMPE Sling, Winch Rope’s main raw material is HMPE fiber. The extraordinary characteristics and extremely high strength of HMPE rope are the reasons why it is often used as a substitute for steel wire/rope, so it is often used for cutting-resistant gloves and clothes, climbing equipment, fishing lines, suspension lines of sports parachutes and paragliders, and so on. HMPE ropes are specially heat-resistant and UV-resistant. They have extremely low friction coefficient, and greatly reduce the operating cost. Compared with steel wire ropes, they provide a safer treatment scheme. They are used for slings, mooring ropes and winch ropes, as well as anti-cracking reinforcement of luggage fabrics, and fishing and fish-raising nets. Their excellent comprehensive performance makes their application range very wide, and they are very popular in various industries.

A 3-strand HMPE sling is a type of lifting sling made from high-modulus polyethylene fibers. The three strands are braided together to create a strong and durable rope that is capable of supporting heavy loads.

Winch rope, on the other hand, is a rope specifically designed for use with a winch. It is typically made from synthetic fibers, such as nylon or HMPE, and is used to pull heavy objects or vehicles.

While both a 3-strand HMPE sling and winch rope are used for heavy lifting, their specific applications differ. The sling is typically used to lift and move objects from one place to another, while winch rope is used to pull objects towards the winch. Additionally, the 3-strand HMPE sling is braided together while winch rope may come in various forms such as braided or twisted.

Specifications:

| Material: |

High modulus polyethylene |

| Strands: |

3, 8, 12 or as required |

Color:

|

Blue or according to your need |

| Specific Density: |

Approx. 0.98 (floats) |

| Melting point: |

Approx. 150℃ |

| Abrasion resistance: |

Excellent |

| UV resistance: |

Good |

| Chemical resistance: |

Excellent |

| The elongation: |

3~4% |

| Coil length: |

220m |

| Spliced strength: |

±10% |

Weight and length tolerance:

|

±5% |

| Packaging: |

Woven bags, wire coils or according to customer requirements |

| Certifications: |

CCS, BV, ABS, DNV, KR, NK, RS, LR, RINA |

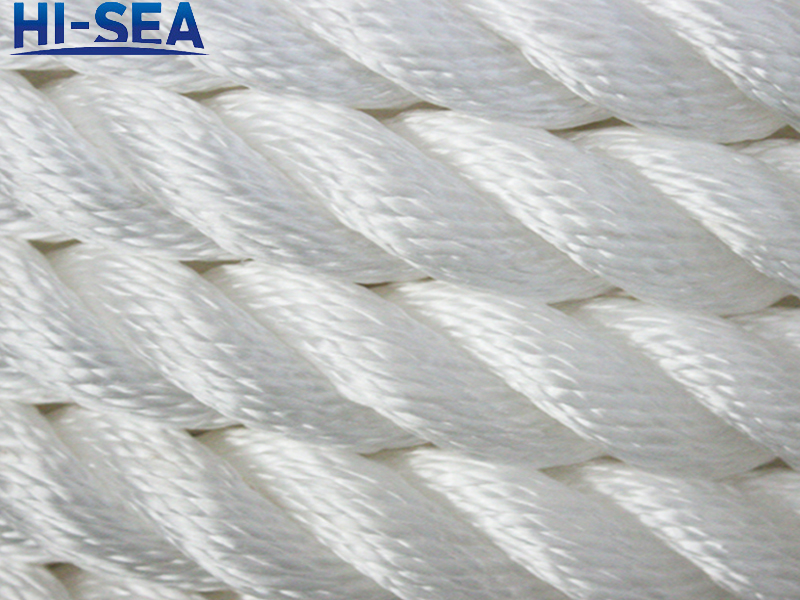

Product Display: