Made in China, 8 or 12 Strands of HMPE Rope

Description:

Made in China, 8 or 12 Strands of HMPE Rope belongs to synthetic fiber rope, which is slightly high and has superior performance. Use synthetic fiber rope, no dangerous wire fragments. The fiber rope has no yield point, the fiber rope has no water absorption or corrosion, and there is no strength loss when the synthetic fiber is overlapped on the winch drum. No kink, no recoil, torque balance. The fiber rope is wear-resistant and ultraviolet-resistant. After chemical exposure, the synthetic fiber rope can keep 100% strength. At about 60% breaking load, the steel wire reaches its yield point, beyond which the steel wire will be permanently and irrevocably deformed. Not only will any stretching not recover, but the steel wire becomes harder and more brittle, and it must be scrapped immediately. Therefore, in this case, high-performance fiber rope is a better choice.

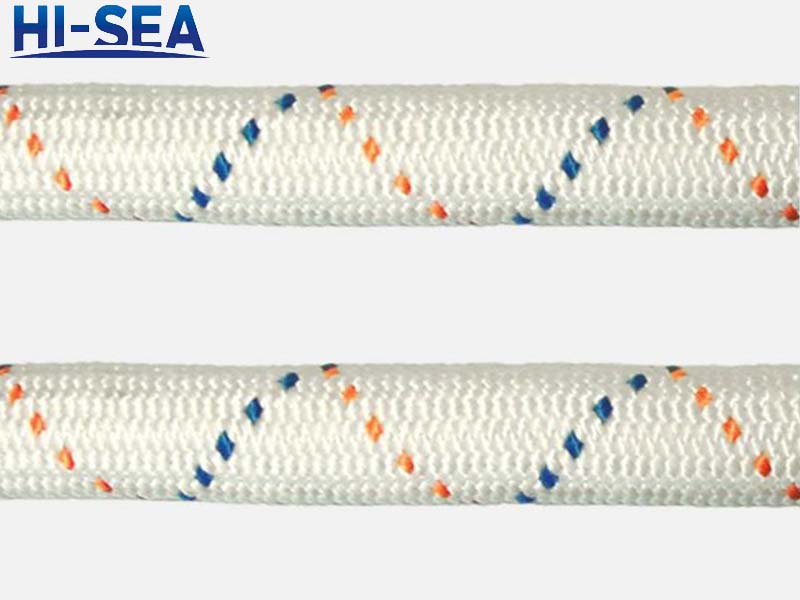

The HMPE (High-Modulus Polyethylene) rope, also known as Dyneema, is a type of rope that is lightweight and incredibly strong, making it ideal for a range of applications, including marine, industrial, and military. The rope is made from high-quality HMPE fibers that are braided together to form either 8 or 12 strands, depending on the specific application requirements.

When it comes to the manufacturing of HMPE ropes, China has become a significant player in recent years, producing high-quality ropes that meet the standards of the international market. The ropes are typically made in a specialized manufacturing facility using advanced technology and equipment to ensure consistent quality and performance.

The 8 or 12 strand configuration of the HMPE rope provides increased strength and durability, making it ideal for demanding applications such as mooring lines, towing lines, and winch lines. The rope’s construction also provides excellent resistance to abrasion, chemicals, and UV rays, making it suitable for use in harsh environments.

Overall, the Made in China HMPE rope provides an excellent combination of strength, durability, and performance, making it a popular choice for a range of applications across various industries.

Specifications:

| Material: |

High modulus polyethylene |

| Strands: |

8, 12 or as required |

Color:

|

Yellow or according to your need |

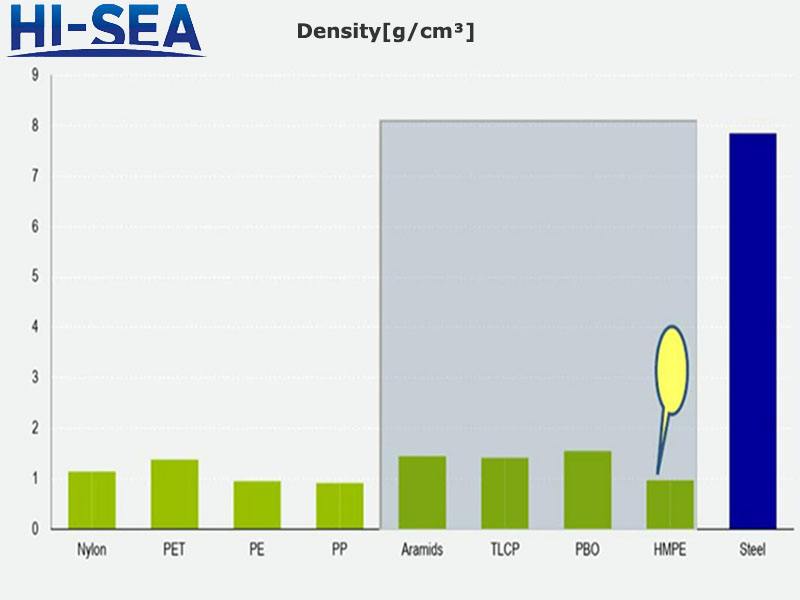

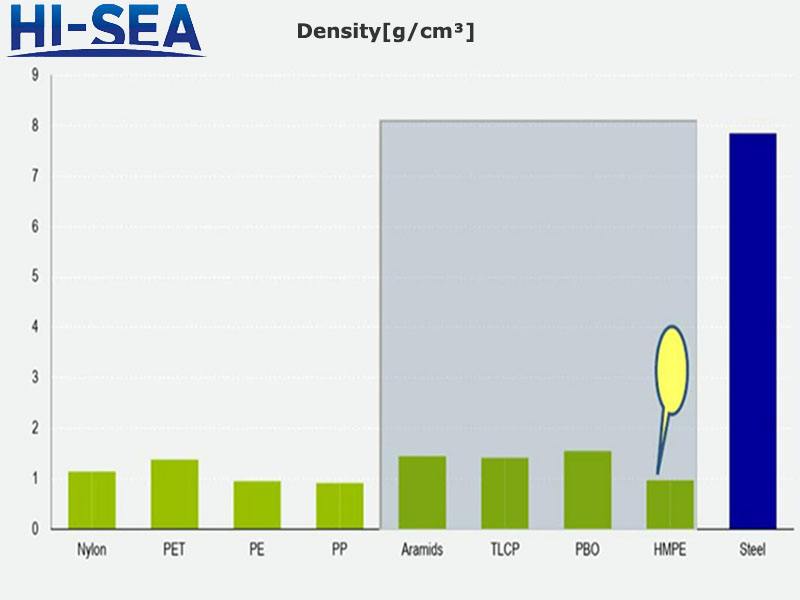

| Specific Density: |

Approx. 0.98 (floats) |

| Melting point: |

Approx. 150℃ |

| Abrasion resistance: |

Excellent |

| UV resistance: |

Good |

| Chemical resistance: |

Excellent |

| The elongation: |

3~4% |

| Coil length: |

220m |

| Spliced strength: |

±10% |

Weight and length tolerance:

|

±5% |

| Packaging: |

Woven bags, wire coils or according to customer requirements |

| Certifications: |

CCS, BV, ABS, DNV, KR, NK, RS, LR, RINA |