High Modulus Polyethylene High Strength Rope, Wear-Resistant Rope

Description:

High modulus polyethylene high strength rope, also known as HMPE rope, is a type of synthetic fiber rope with an exceptionally high strength-to-weight ratio. It is made from a type of polyethylene that has a very high molecular weight, giving it an extremely strong and durable construction.

High Modulus Polyethylene High Strength Rope, Wear-Resistant Rope is specially treated to strengthen its wear resistance. In addition, the strength of polymer polyethylene fiber is very high among synthetic fibers, and its strength can reach 1.5 times that of steel wire of the same specification. The rope made of it has the characteristics of ultraviolet radiation resistance, seawater resistance, acid and alkali resistance, fatigue resistance, weather temperature difference resistance, prolonged service life and so on. High-modulus polyethylene rope has good stability, good damage resistance in use, and can be guaranteed in use time. Secondly, the high modulus polyethylene rope has a shielding effect, even after being irradiated, no other reaction will occur, and this kind of rope also has a good light shielding effect. One of the most important characteristics of HMPE rope is its high tensile strength, which makes it ideal for use in applications where strength and durability are critical. In addition to its strength, HMPE rope is also highly resistant to wear and abrasion, which makes it well-suited for use in harsh environments and applications where the rope is exposed to heavy loads or rough surfaces.

HMPE rope is commonly used in a variety of industries, including marine, offshore, and industrial applications. It is often used for mooring and towing ships, as well as for lifting heavy loads in construction and industrial settings. Its high strength and wear resistance also make it popular for use in high-performance sports and outdoor activities, such as climbing and sailing.

Specifications:

| Material: |

High modulus polyethylene |

| Strands: |

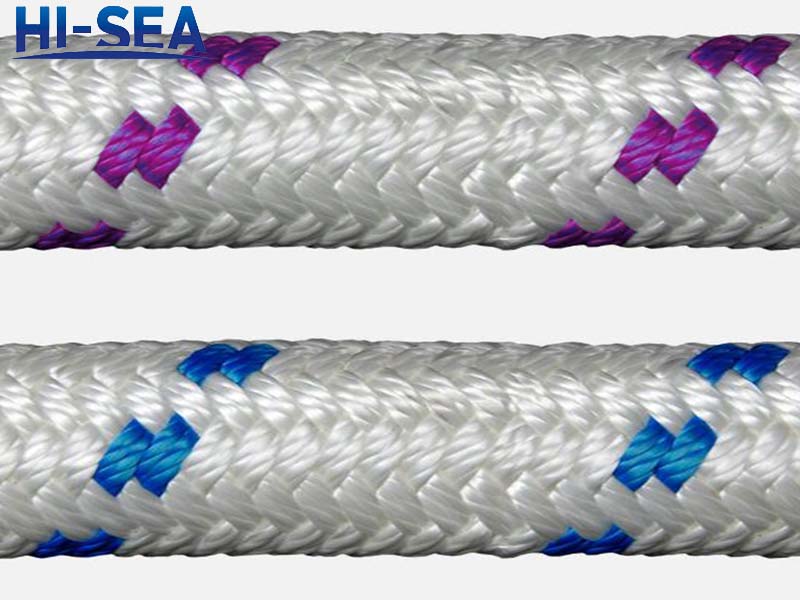

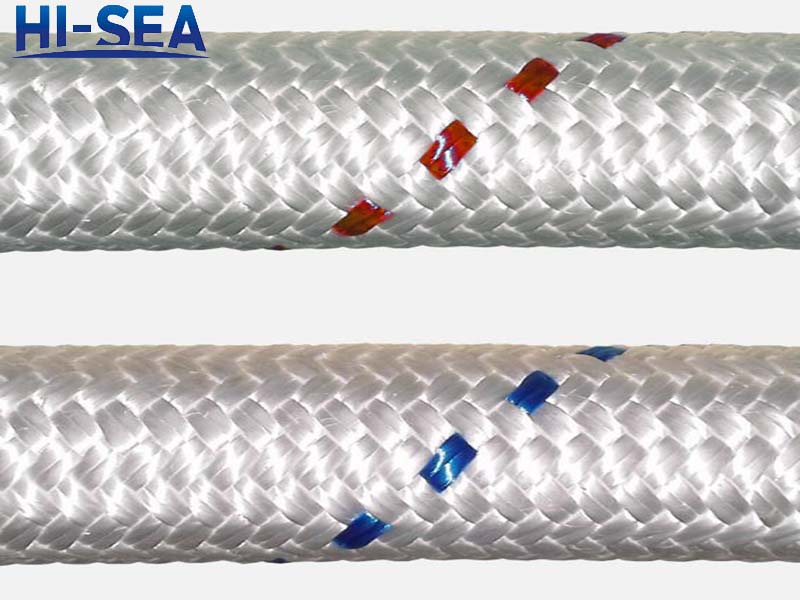

3, 8, 12 or as required |

Color:

|

Blue or according to your need |

| Specific Density: |

Approx. 0.98 (floats) |

| Melting point: |

Approx. 150℃ |

| Abrasion resistance: |

Excellent |

| UV resistance: |

Good |

| Chemical resistance: |

Excellent |

| The elongation: |

3~4% |

| Coil length: |

220m |

| Spliced strength: |

±10% |

Weight and length tolerance:

|

±5% |

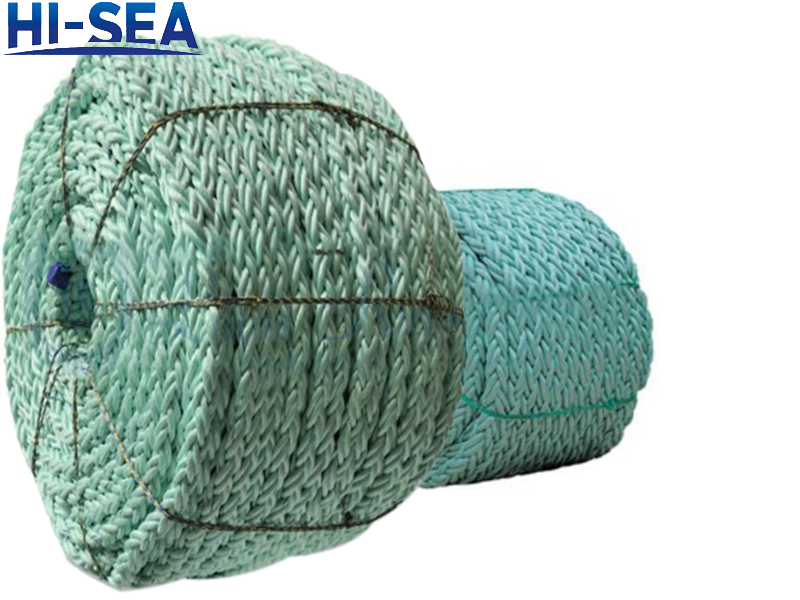

| Packaging: |

Woven bags, wire coils or according to customer requirements |

| Certifications: |

CCS, BV, ABS, DNV, KR, NK, RS, LR, RINA |