High Wear-Resistant and Strong UHMWPE Mooring Rope

Description:

UHMWPE (Ultra-High-Molecular-Weight Polyethylene) mooring ropes are a type of synthetic rope that is known for its exceptional strength and wear-resistance. These ropes are widely used in marine and offshore industries for various applications such as mooring ships, offshore drilling, and towing.

One of the unique features of UHMWPE mooring ropes is their high strength-to-weight ratio, which makes them significantly stronger than traditional ropes made of materials like nylon or polyester. Additionally, UHMWPE ropes are highly resistant to abrasion, UV radiation, and chemical degradation, making them ideal for use in harsh marine environments.

The high wear-resistance of UHMWPE mooring ropes ensures that they have a long service life and require less frequent replacement than other types of ropes. Furthermore, they have excellent resistance to bending fatigue, which means they can withstand repeated cycles of loading and unloading without experiencing significant degradation.

Overall, UHMWPE mooring ropes are a durable and reliable option for any marine or offshore application that requires a strong, wear-resistant rope that can withstand harsh environments and frequent use.

Main Performance Indexes of UHMWPE Materials:

| Product Performance |

Units |

UHMWPE-PE, M-A |

UHMWPE-PE, M-B |

UHMWPE-PE, M-C |

| Specific Density: |

g/cm³ |

0.94-0.98 |

9.08-1.08 |

1.05-1.20 |

| Tensile Strength: |

MPa |

> 20 |

> 20 |

> 18 |

| Breaking Elongation: |

% |

> 150 |

> 100 |

> 50 |

| Vicat Softening Point(VSP): |

℃ |

> 120 |

> 130 |

> 130 |

| Water Absorption: |

% |

< 0.01 |

< 0.01 |

< 0.01 |

| Frictional Coefficient: |

|

< 0.09 |

< 0.09 |

< 0.09 |

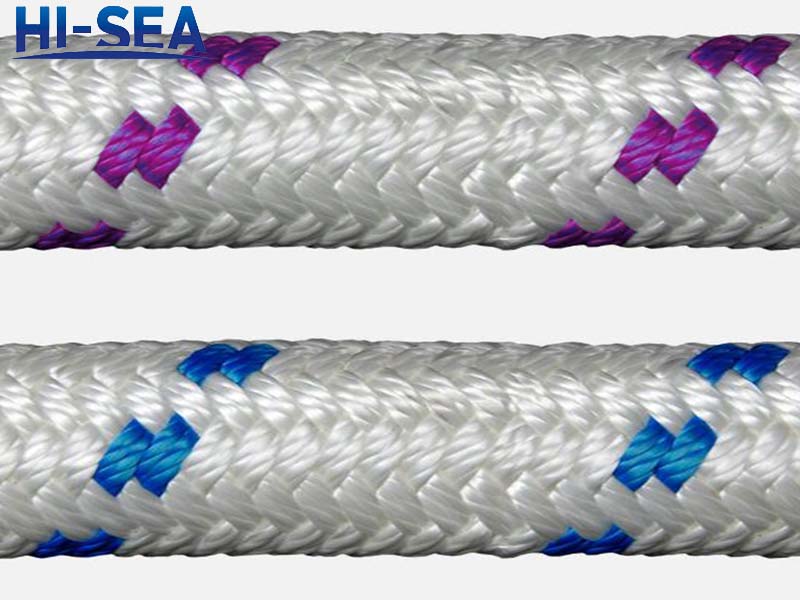

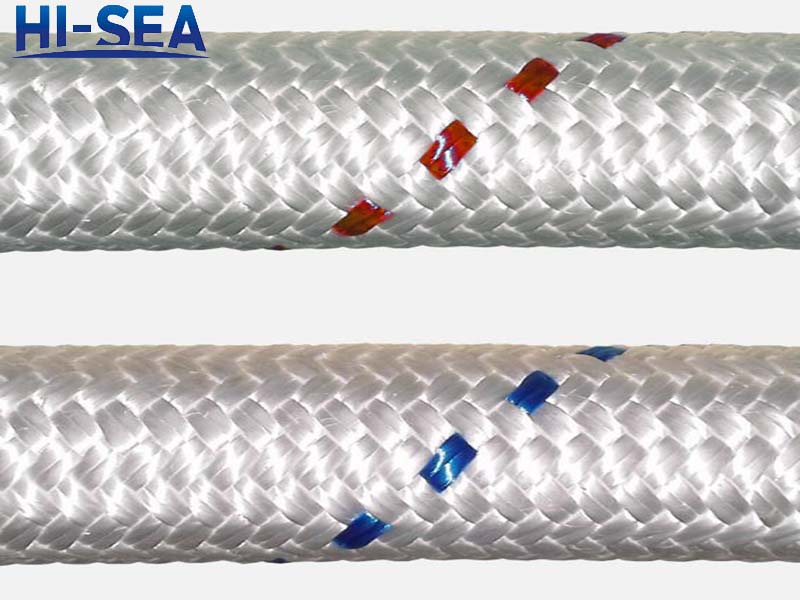

Product Specifications:

| Material: |

UHMWPE |

| Strands: |

8, 12, 16 or as required |

| Specific Density: |

Approx. 0.97, Floating |

| Melting point: |

145℃ |

| Abrasion resistance: |

Excellent |

| UV resistance: |

Excellent |

| Chemical resistance: |

Excellent |

| The elongation: |

3~4% |

| Coil length: |

220m |

| Spliced strength: |

±10% |

| Weight and length tolerance: |

±5% |