Polyester and Polypropylene Mixed Mooring Tail

Description:

The Polyester and Polypropylene Mixed Mooring Tail is a unique and innovative product designed for marine applications, specifically for mooring and anchoring vessels. It combines the desirable properties of both polyester and polypropylene fibers to offer enhanced performance and durability.

The mooring tail is composed of a blend of polyester and polypropylene fibers, carefully engineered to optimize strength, flexibility, and resistance to environmental factors. Polyester fibers are known for their high tensile strength and excellent resistance to UV radiation and abrasion. Polypropylene fibers, on the other hand, provide exceptional buoyancy, low water absorption, and good resistance to chemicals.

By combining these two materials, the mooring tail achieves a balance of strength and buoyancy, making it suitable for various marine conditions. The polyester component provides the necessary strength to withstand high loads and harsh weather conditions, while the polypropylene component ensures buoyancy and reduces the overall weight of the tail.

This mixed mooring tail offers several advantages over traditional mooring tails made of a single material. Its unique composition enhances its ability to handle dynamic loads, reduces the risk of rope sinking, and provides excellent resistance to UV degradation, saltwater corrosion, and general wear and tear. Furthermore, the blended fibers reduce the risk of hockling and kinking, ensuring smooth and reliable operation during mooring and anchoring procedures.

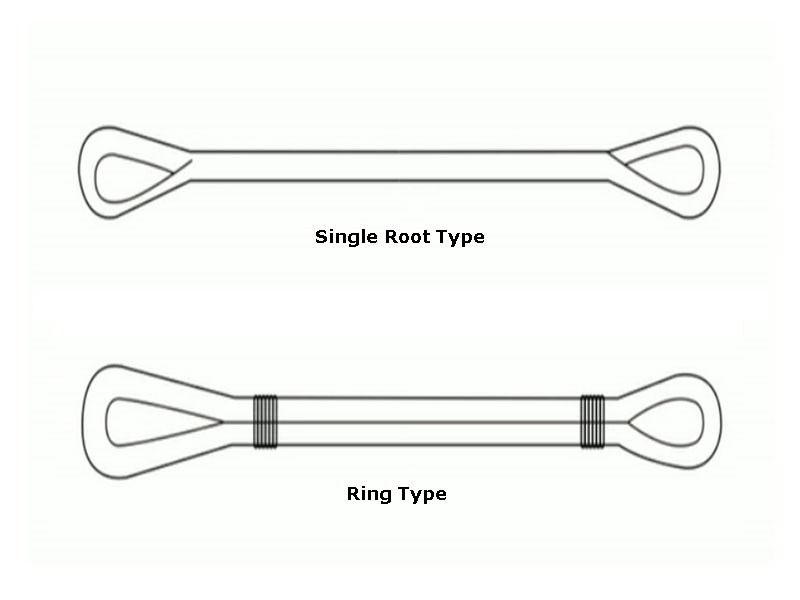

The mooring tail is available in various lengths and diameters to accommodate different vessel sizes and mooring requirements. It is typically equipped with professionally spliced and reinforced thimbles or eyes at both ends for secure attachment to the vessel and anchor points.

Main Performance of PP and PET Mixed Material:

| Material |

Polyester and Polypropylene mixed |

| Strands |

3, 8, 12, 16 or as required |

Color

|

As your needs |

| Specific Density |

0.97-1.1, Depending on proportion |

| Melting point |

165℃/260℃ |

| UV resistance |

Good |

| Chemical resistance |

very good |

| Abrasion resistance |

Very good |

| Packing |

Packaged with bags, standard export carton or as your request |

Certifications

|

ABS, CCS, ISO, NK, BV, LR, RS, etc. |