High Performance Polyethylene Rope

Description:

High performance polyethylene rope, also known as HPPE rope, is a versatile and durable synthetic rope that offers exceptional strength and durability. It is made from a specific type of high-density polyethylene (HDPE) fibers, which are known for their excellent tensile strength and resistance to abrasion, chemicals, and UV radiation.

HPPE rope is renowned for its outstanding strength-to-weight ratio, making it significantly stronger than traditional ropes while remaining lightweight. This characteristic makes it a popular choice for various demanding applications where strength and reliability are crucial.

One of the remarkable features of HPPE rope is its exceptional tensile strength. It can withstand high loads without stretching or deforming, making it suitable for heavy-duty tasks such as lifting, towing, and mooring. Additionally, its resistance to abrasion ensures longevity even in rugged environments, reducing the risk of fraying or breaking under harsh conditions.

The chemical resistance of high-performance polyethylene rope allows it to perform reliably in corrosive environments, such as marine or industrial settings. It is resistant to many chemicals, including acids, alkalis, and solvents, which enhances its durability and suitability for a wide range of applications.

Another advantage of HPPE rope is its resistance to UV radiation. Unlike some natural fibers or other synthetic ropes, high-performance polyethylene rope does not degrade or weaken when exposed to sunlight over extended periods. This UV resistance ensures its longevity and makes it an excellent choice for outdoor applications, including boating, camping, and general-purpose activities.

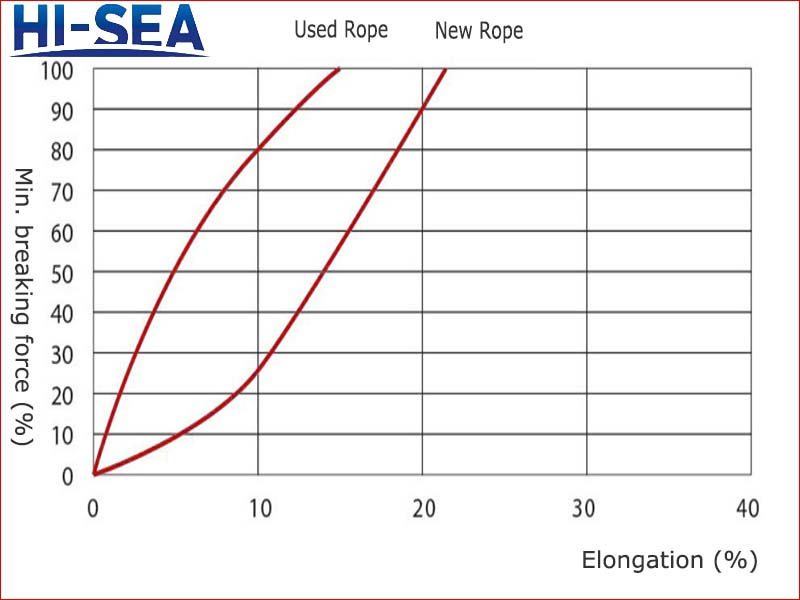

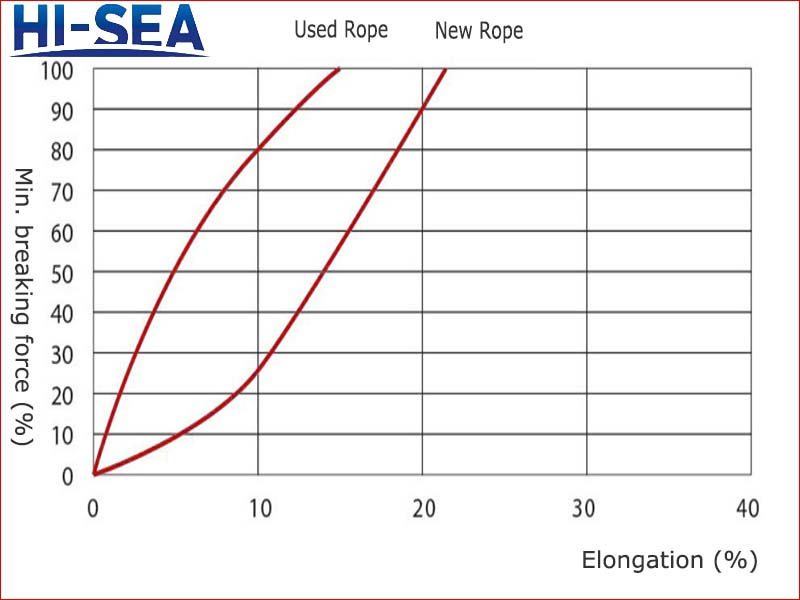

Furthermore, HPPE rope is known for its low stretch properties. It exhibits minimal elongation under high loads, providing greater stability and control during operations. This low stretch characteristic is particularly beneficial for applications where precision and accuracy are crucial, such as sail rigging, construction, or rescue operations.

Due to its exceptional properties, high-performance polyethylene rope finds applications in various industries and sectors. It is commonly used in marine activities, including sailing, fishing, and offshore operations, where its strength and resistance to corrosion are highly valued. Additionally, it is employed in construction, agriculture, transportation, and sports and recreation, among other fields, where a reliable and durable rope is essential.

In summary, high-performance polyethylene rope is a versatile and reliable synthetic rope that combines exceptional strength, low stretch, chemical resistance, UV resistance, and durability. Its outstanding characteristics make it a preferred choice for demanding applications where reliability and performance are critical.

Main Performance of Polyethylene Material:

| Material |

Polyethylene fiber(Not all) |

| Spec. density |

0.93, Floating |

| Melting Point |

Approx. 140°C |

| U.V. Resistance |

Very good |

| Abrasion resistance |

Very good |

| Chemical resistance |

Good |

| Elongation |

14% |

Specification of Polyethylene Fiber Rope:

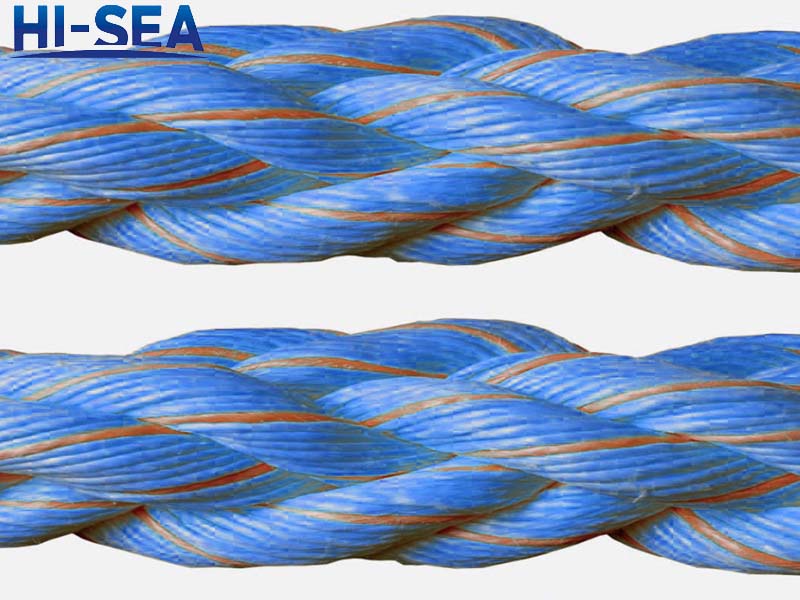

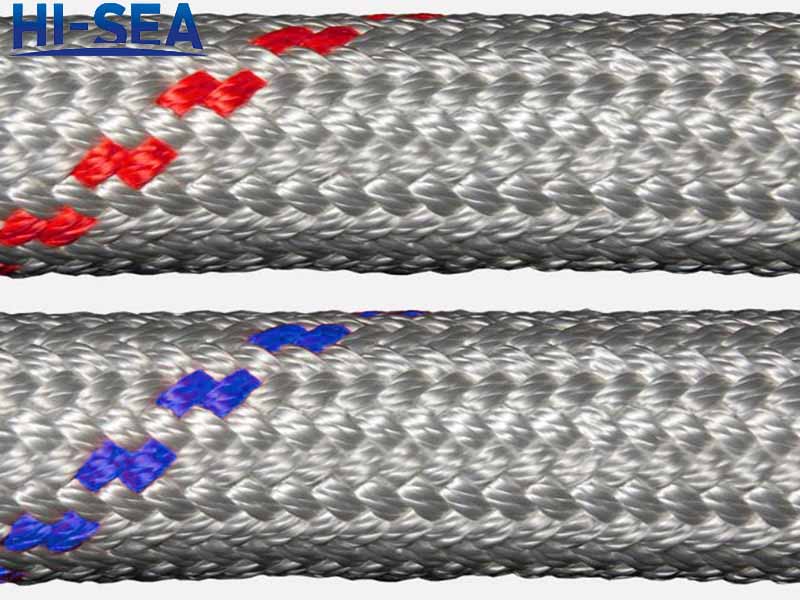

1. Material: Polyethylene fiber(PP);

2. Strands: 8, 12 strands or as required;

3. Color: Different colors on reqirement;

4. Packing: Packaged by coil or reel or as your requirements;

5. Application: Ocean transportation, Fishing, Harbor mooriing etc.;

6. Certifications: ABS, CCS, ISO, NK, BV, LR, RS, etc.

Elongation:

Characteristics:

1. Easy to operate

2. Floating in water but not absorbing

3. Light weight and high strength

4. High extensibility and good wear resistance