High Strength UHMWPE Strong Mooring Rope and Towing Rope

Description:

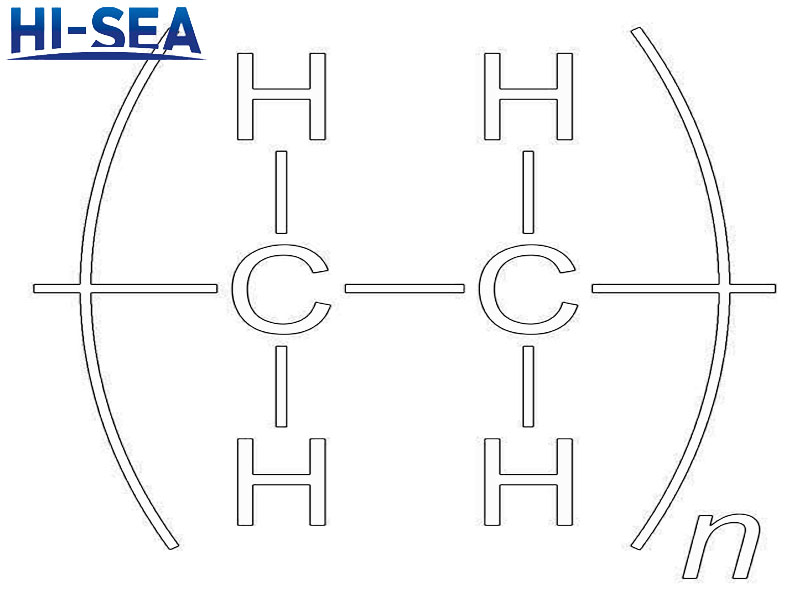

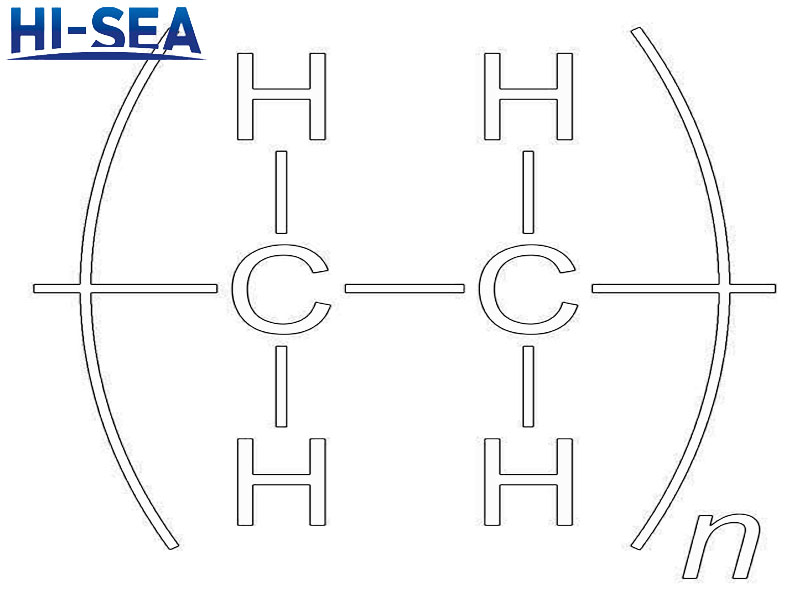

The raw materials of High Strength UHMWPE Strong Mooring Rope and Towing Rope are UHMWPE fiber, high molecular weight polyethylene (UHMWPE) fiber, which is made of ultra-high molecular weight polyethylene with a molecular weight of more than 5 million. With its inherent high orientation and high crystallization, it forms unique ultra-high strength and modulus. It has the characteristics of ultra-high strength, ultra-high modulus, light specific gravity, low elongation at break, ultraviolet radiation resistance, chemical corrosion resistance, wear resistance and cutting resistance. It is widely used in marine towing ropes and mooring ropes, anchor ropes of offshore oil platforms, hoisting ropes and so on.

(UHMWPE Molecular Structure)

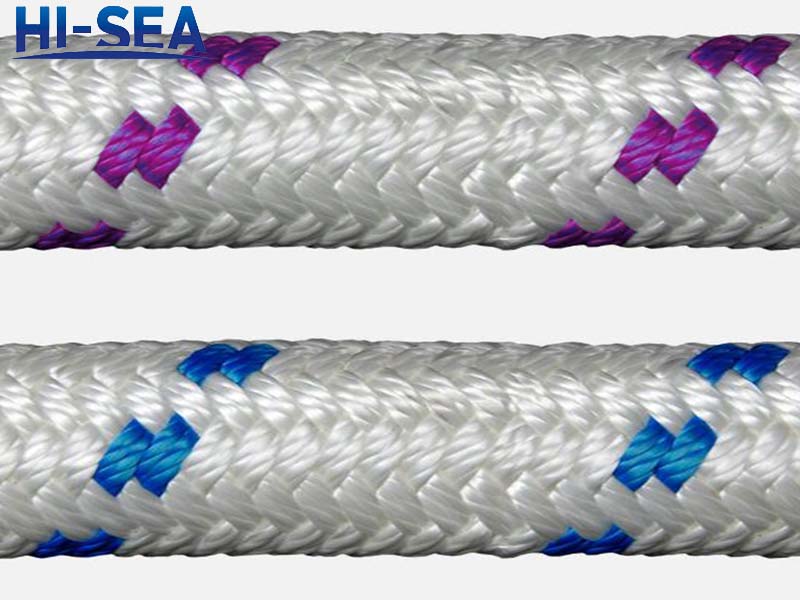

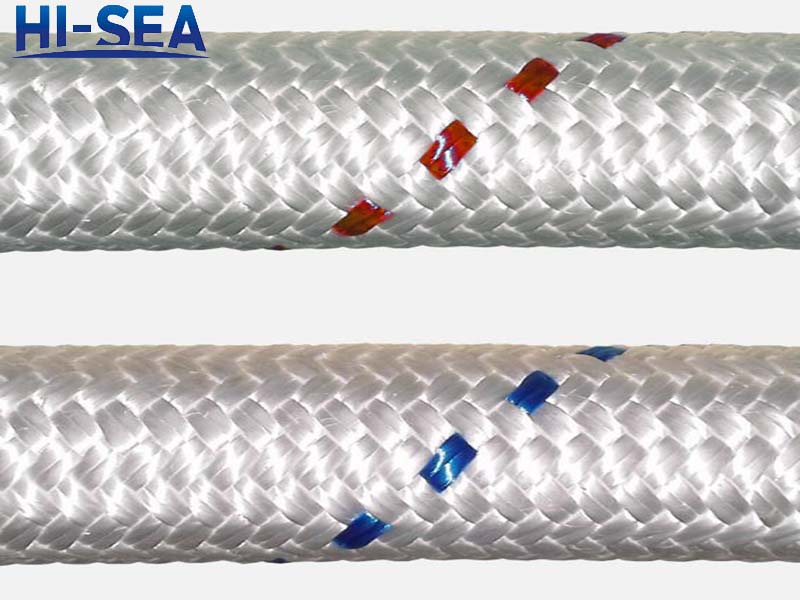

High Strength UHMWPE Strong Mooring Rope and Towing Rope is a type of rope made of ultra-high molecular weight polyethylene (UHMWPE) fibers that are known for their exceptional strength-to-weight ratio, high abrasion resistance, and low stretch properties. These ropes are commonly used in maritime applications such as mooring and towing, as well as in other heavy-duty industries like construction, mining, and oil and gas exploration. UHMWPE mooring and towing ropes are highly durable and have a longer lifespan than traditional ropes made of materials such as nylon or polyester. Additionally, these ropes are resistant to chemicals and UV radiation, making them ideal for use in harsh environments. Overall, UHMWPE strong mooring and towing ropes are a reliable and efficient solution for heavy-duty applications.

Main Performance Indexes of UHMWPE Materials:

| Product Performance |

Units |

UHMWPE-PE, M-A |

UHMWPE-PE, M-B |

UHMWPE-PE, M-C |

| Specific Density: |

g/cm³ |

0.94-0.98 |

9.08-1.08 |

1.05-1.20 |

| Tensile Strength: |

MPa |

> 20 |

> 20 |

> 18 |

| Breaking Elongation: |

% |

> 150 |

> 100 |

> 50 |

| Vicat Softening Point(VSP): |

℃ |

> 120 |

> 130 |

> 130 |

| Water Absorption: |

% |

< 0.01 |

< 0.01 |

< 0.01 |

| Frictional Coefficient: |

|

< 0.09 |

< 0.09 |

< 0.09 |

Main Advantages:

Low weight, low creep and low maintenance.

High efficiency, high toughness and high elastic modulus.

Good cold resistance, chemical resistance and good fatigue resistance.